Learn how Mile’s delivery management system helps you streamline your e-commerce order fulfillment for improved efficiency and customer satisfaction.

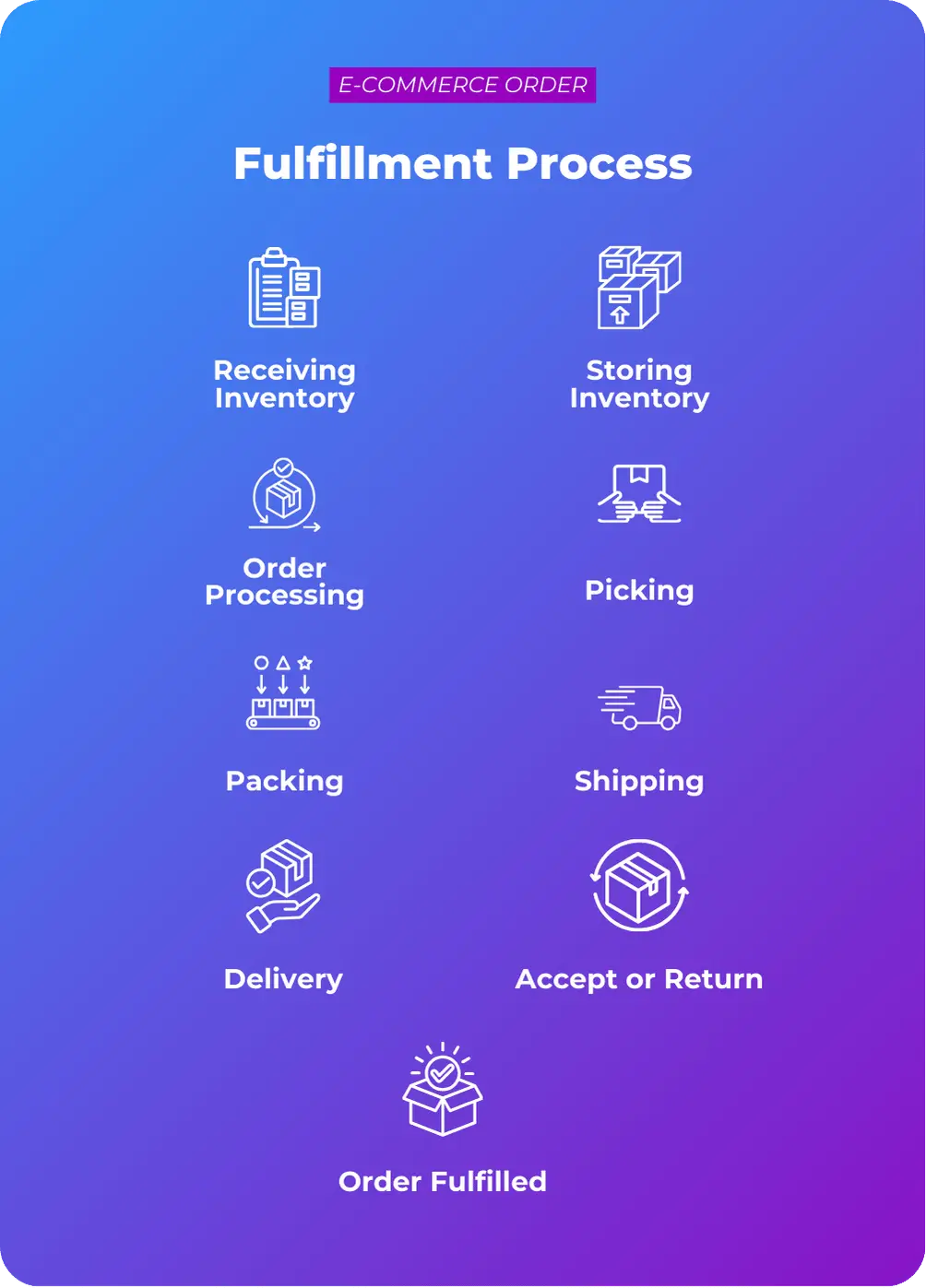

In simplest terms, e-commerce order fulfillment refers to the act of receiving an order on an e-commerce sales channel, picking the ordered items in a warehouse or fulfillment center, packing them in branded packaging, dispatching the package by in-house or third-party logistics (3PL) provider, and delivering it to the customer. Sometimes, it also includes returns, refunds, and exchanges.

For online retailers, a new order on the docket is hardly cause for celebration. The real joy begins only once the customer receives the order at their desired time and in their desired condition. This is because there’s a good chance that one successfully fulfilled order will multiply into tens and hundreds of orders.

Thus, it’s important to perform each step in the e-commerce order fulfillment process scrupulously to ensure customers receive their orders accurately and on time.

7 Steps to Successful E-Commerce Order Fulfillment

1. Receiving Inventory

The first step in the order fulfillment process involves receiving inventory. Goods can arrive from multiple sources: third-party suppliers, internal company departments, warehouses, or even as digital data from databases. The form in which inventory arrives can vary widely, ranging from physical products to fluids delivered through pipelines or digital files.

Upon arrival, the inventory is carefully counted, inspected, and recorded to confirm that the correct quantities have been received and that they meet the required quality standards. A barcode or stock keeping unit (SKU) generator assigns a unique alphanumeric code to each product by incorporating specific attributes such as category, brand, size, and color, which helps businesses efficiently track and manage inventory. These barcodes or SKUs are used to streamline the receiving process and to facilitate the later retrieval of items from storage.

2. Storing Inventory

Once inventory is received, it is either immediately distributed or stored for future use. The objective of inventory storage is to organize products in a manner that supports efficient order fulfillment, rather than holding stock for extended periods of time. Items are categorized into short-term or long-term storage based on anticipated demand. Proper storage management ensures that products are easily accessible for picking when orders are placed.

To evaluate inventory efficiency, businesses can calculate inventory days on hand by dividing the average inventory by the daily cost of goods sold (COGS). This calculation reveals the average number of days the inventory will last before it will need to be replenished.

3. Order Processing

Order processing begins as soon as a customer places an order. An order management system, which is often integrated with the shopping cart on an e-commerce website, automatically triggers the fulfillment process. This system coordinates the picking and packing activities and ensures that the products are selected and prepared for shipment according to the customer’s order specifications.

4. Picking

The picking process involves selecting the correct items from the warehouse based on the details provided on a packing slip. This slip includes crucial information such as the SKUs, product colors, sizes, quantities, and the specific location of the items within the warehouse. Picking can be performed by a team of workers or through the use of automated systems, such as warehouse robots, which can enhance speed and accuracy.

5. Packing

After the items have been picked, they move on to the packing stage. Here, the goal is to select packing materials that will minimize the dimensional weight of the package. Dimensional weight is calculated by multiplying the package’s length, width, and height. Since shipping costs are often based on dimensional weight, optimizing this aspect of packing can help reduce shipping expenses.

Packing teams may also include return shipping materials and labels in case the customer needs to return or exchange the product. This proactive step facilitates smoother returns processing later.

6. Shipping

Once packed, the order is handed off to a shipping carrier. This can be an in-house resource or a 3PL provider. The carrier determines the shipping costs based on either the actual weight of the package or its dimensional weight, whichever is greater. To avoid unnecessary costs, it’s essential to pack items efficiently to keep the dimensional weight as low as possible.

Carriers also often have specific packaging requirements that must be met to ensure timely and cost-effective delivery. Non-compliance with these requirements can lead to delays if the carrier refuses to accept the shipment.

7. Delivery

The growth of e-commerce has not only changed the way we shop but also the way we want our orders delivered. The rising customer preference for the speed, convenience, and affordability of receiving an order has led many e-commerce sellers to add multiple delivery options in order to satisfy customer expectations.

Each option provides a unique level of speed, convenience, and cost-effectiveness to meet different customer needs.

- Same-day delivery: Items are delivered within hours of purchase.

- Next-day delivery: This ensures arrival the following day.

- Time-slot delivery: This allows customers to choose a specific delivery window.

- Standard delivery: This is a cheaper option but takes 3-5 business days.

- In-store pick-up: Shoppers collect their purchases directly from a store.

- Click-and-collect: This is similar to in-store pick-up but the collection happens from designated locations.

Returns Processing (Optional)

Though optional, returns processing is an integral part of the order fulfillment process. It begins with the inclusion of return shipping materials and a label in the original shipment to the customer. If a customer decides to return a product, the process involves several steps to determine whether the item can be restocked. Quality control checks are conducted to assess the condition of the returned product. If it is in good condition, it may be returned to inventory. However, if the product is defective, damaged, or soiled, it may need to be returned to the vendor for a refund, sent back to the manufacturer, or disposed of appropriately, like through recycling, for instance.

Each of these steps is crucial to ensuring a smooth and efficient order fulfillment process. By effectively managing each stage, companies can improve customer satisfaction, reduce costs, and streamline their operations. Whether dealing with physical products or digital goods, a well-executed order fulfillment process is essential for any business that aims to deliver high-quality service to its customers.

Top 5 Best Practices for E-Commerce Order Fulfillment

As online shopping becomes the norm of the day, it gets all the more important for 3PL providers to streamline their workflows in order to ensure that consumers receive their orders quickly, accurately, and efficiently. Below, we have listed seven best practices for e-commerce order fulfillment for 3PLs.

Seamless Integrations and Workflows

As we mentioned above, it takes at least seven steps to bring about a successfully fulfilled order. Instead of handling each step individually on different systems, it’s better to integrate your warehouse management, order processing, delivery management, and reverse logistics onto a single, unified platform to consolidate the order fulfillment process.

Pro Tip: Switch to Mile!

Mile’s comprehensive delivery management solution with warehousing, inventory, and order management modules seamlessly integrate with various e-commerce sales channels to facilitate smoother data exchange and improve overall efficiency.

It also comes with a reverse logistics management module that helps you track and manage returned products and process them in the inventory properly. But, above all, Mile offers real-time returns in the field, as it allows drivers to mark items as rejected/returned in the field and update the cash-on-delivery amount instantly. This system eliminates the need for a second trip to collect returns, reduces warehouse delays, and ensures a smooth, transparent returns process for both drivers and customers.

Automation Technologies

Warehouse automation greatly enhances the speed and accuracy of warehouse operations. For example, mobile barcode scanning, pick-to-light systems, and automated packing stations reduce the risk of human error significantly.

Automation drives positive outcomes in dispatch processes too. When zone assignments are automated and routes are optimized through advanced artificial intelligence (AI) and machine learning (ML) algorithms, 3PLs no longer have to spend hours assigning orders and zones to drivers and charting optimal routes manually. Besides shortening delivery cycles, this technology also helps them scale their operations to meet growing consumer demands for same-day deliveries.

Pro Tip: Switch to Mile!

Mile’s delivery management solution is packed with advanced features to optimize logistics. It includes predictive AI-powered dispatching with a configurable rules engine and zonal AI-driven order distribution for efficient deliveries. The solution also supports waybill generation and scanning, route optimization with geo-fencing, and heat maps. Additionally, it features AI handwriting recognition and ML-based 3D object scanning to accurately measure packages.

Real-Time Inventory Tracking

Just as it is important for brick-and-mortar retailers, for online retailers too, real-time inventory visibility is essential to maintaining accurate stock levels, preventing stockouts, and minimizing backorders. A robust order fulfillment process should include an integrated real-time inventory tracking system that can be accessed from any location, at any time.

Pro Tip: Switch to Mile!

Mile’s technology assigns your warehouse inventory unique SKUs and barcodes. This allows you to scan and verify picked and packed items with complete accuracy. The barcode scan adds an extra layer of quality control and ensures real-time visibility of your inventory.

Effective Communication with Clients

If you maintain clear communication with e-commerce clients, successful third-party fulfillment becomes that much easier. By updating them on inventory levels, order status, and any potential problems, you build trust and empower them to plan better.

Pro Tip: Switch to Mile!

Mile’s integrated logistics solution comes with a merchant portal and driver app to facilitate end-to-end visibility into a delivery process and streamline real-time communication between all the stakeholders involved in it.

Commitment to Continuous Improvement

If you want to stay ahead of the competition, you must assess and refine your order fulfillment workflows from time to time. Review performance metrics regularly, identify areas for improvement, and implement required changes. This proactive approach will ensure that your 3PL business remains agile and responsive to the evolving needs of the market.

Pro Tip: Switch to Mile!

Mile’s advanced reporting and predictive analytics features offer valuable insights into your fulfillment operations. They will help you manage fluctuating order volumes and make data-driven decisions that drive continuous improvement.

Want to see Mile in action? Schedule a demo today!